- <

TGA2005

TG Series - Customized 2 meters ~ 16 meters

Double Column Surface Grinder TG Series

Hone Right provides comprehensive technical expertise and support. When you purchase a Hone Right gantry-type surface grinder, you not only acquire a machine of excellent quality but also benefit from the most comprehensive technical assistance and service. With over two decades of practical experience in surface grinding, Yashang is well-positioned to offer customers rich expertise in grinding techniques. We are always ready to address any processing and grinding-related issues.

We are also attentive to your needs and requirements. We offer customized machines to meet your specific processing challenges and precision demands.

Feature

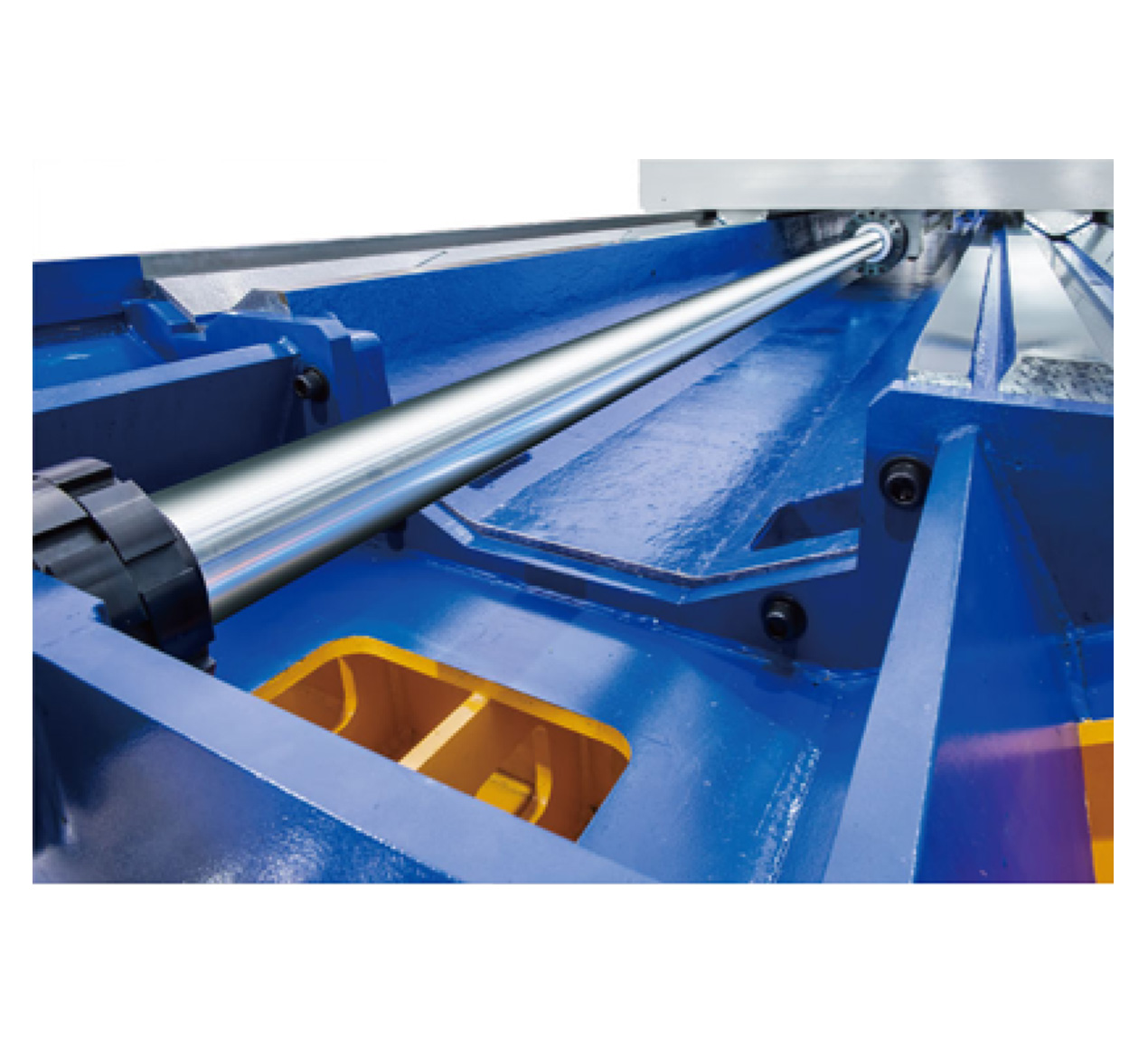

Oil Film Surrounded Spindle

The wheel spindle is supported by a metal bushing which is surrounded by an oil film. This reduces heat friction, abnormal wear and provides smooth operation for a better surface finish.

X-axis Driven by Hydraulic Cylinder

The X-axis movement is driven by a double-acting hydraulic cylinder, featuring smooth motion without deformation or oil leakage problem.

X-axis moving speed can be adjusted on the control panel.

The hydraulic system features buffering function to eliminate impact problem at the end of stroke. It not only provides a protection for the hydraulic cylinder but also extends cylinder life.

Double "V" Slidevays on Base

Extra large double "V" slideways on the base effectively increase contact area between mating surfaces. This provides the rigid support for heavy workpiece.

Choice of NC or CNC Control

The surface grinder is available to equip with a NC or CNC control, featuring powerful functions and making grinding operation easy to learn and operate.

Hydraulic Power Unit

The hydraulic power unit employs a powerful device, providing powerful drive for X-axis movement.

Smooth movement on X-axis can be ensured even at low speed.

The cooler enables the hydraulic oil to maintain a constant temperature for reliable operation.

Circulated Lubrication Oil Circuit

Lubrication oil is circulated and detected. In case of lack of oil, the machine stops automatically.

Spindle Oil Cooler

The spindle oil cooler allows the spindle to run at a constant temperature, reducing thermal deformation of the spindle to a minimum.

Specifications

| SPECIFICATION | UNIT | TGA2005 |

|---|---|---|

| Table area (L x W) | m.m. | 5500x2000 |

| Max table load | kg | 12,000 |

| Distance between columns | m.m. | 2,700 |

| Grinding Area | m.m. | 5000x2000 |

| Table travel | m.m. | 5,100 |

| Z-axis travek | ||

| Spindle (Horiz, spindle wheel head) | m.m. | 1,300 |

| Sub-spindle (Vert, spindle wheel head) | m.m. | 1,300 |

| Spindle (Horix, Spindle wheel head) | ||

| Jog down feed | m.m. | 0.001~0.01 |

| Down feed rate | m.m./min | 2-500 |

| Spindle speed | r.p.m. | 900~1100 |

| Motor | HP(KW) | 25(18.5) |

| Grinding wheel size (OD x T x ID)Distance between columns | m.m. | 610x100x203 |

| Sub-spindle (Vert. spindle wheel head) | ||

| Jog down feed | m.m. | 0.001~0.01 |

| Down feed rate | m.m./min | 2-500 |

| Spindle speed | r.p.m. | 1000~1600 |

| Motor | HP(KW) | 15(11) |

| Grinding wheel size (OD x T x ID)Distance between columns | m.m. | 405x80x127 |

| Distance from spindle center to table | m.m. | 1,250 |

| Distance from sub-spindle center to table | m.m. | 1,300 |

| Sub-spindle head tilting degree | degree | ±50° |

| Y-axis motor | HP(KW) | 2.68(2) |

| Z-azis motor | HP(KW) | 2.68(2) |

| Oil tank Motor | HP(KW) | 20 20 |

| Grinding feedrate | m.m./min | 10000~25000 |

| Voltage | V | AC 220 / 380±10% , 50 / 60 Hz±1 Hz |

| Control | PC BASE | |

| Machine height | m.m. | 5,500 |

| Floor space | m.m. | 17000x8500 |

| Machine weight | kg | 79,000 |

Accessories

- Grinding wheel balancing stand

- Grinding wheel balancing arbor for main spindle

- Grinding wheel balancing arbor for sub-spindle

- Wheel flange for main spindle x 2 sets

- Wheel flange for sub-spindle x 2 sets

- Bottom grinding wheel flange for sub-spindle x 2 sets

- Wheel flange extractor

- Wheel flange extractor

- Wheel lifting tool for main spindle

- Standard grinding wheel (Ø610 x 70 x 203) for main spindle x 1 pce

- Standard grinding wheel (Ø105 x 60 x 127) for main spindle x 1 pce

- 50° grinding wheel (Ø405 x 60 x 127) for sub-spindle x 1 pce

- Bottom grinding wheel (Ø205 x 50 x 127) for sub-spindle x 1 pce

- Hydraulic oil cooler

- Circulated cooling temperature display

- Diamond dresser x 2 pcs / set

- Standard magnetic base x 2 pcs

- Stainless steel operation box

- Foundation drawing

- Foundation bolts, leveling bolts and leveling blocks x 1 set

- Electric wiring diagram

- Operation manual

- Tool box

- Spare main spindle assembly

- Spare sub-spindle assembly

- Spare wheel flange for main spindle

- Spare wheel flange for sub-spindle

- Spare bottom grinding wheel flange for sub-spindle

- Wheel dresser for sub-spindle

- Semi-enclosed stainless steel guard

- Specified machine color