- <

Energy-13

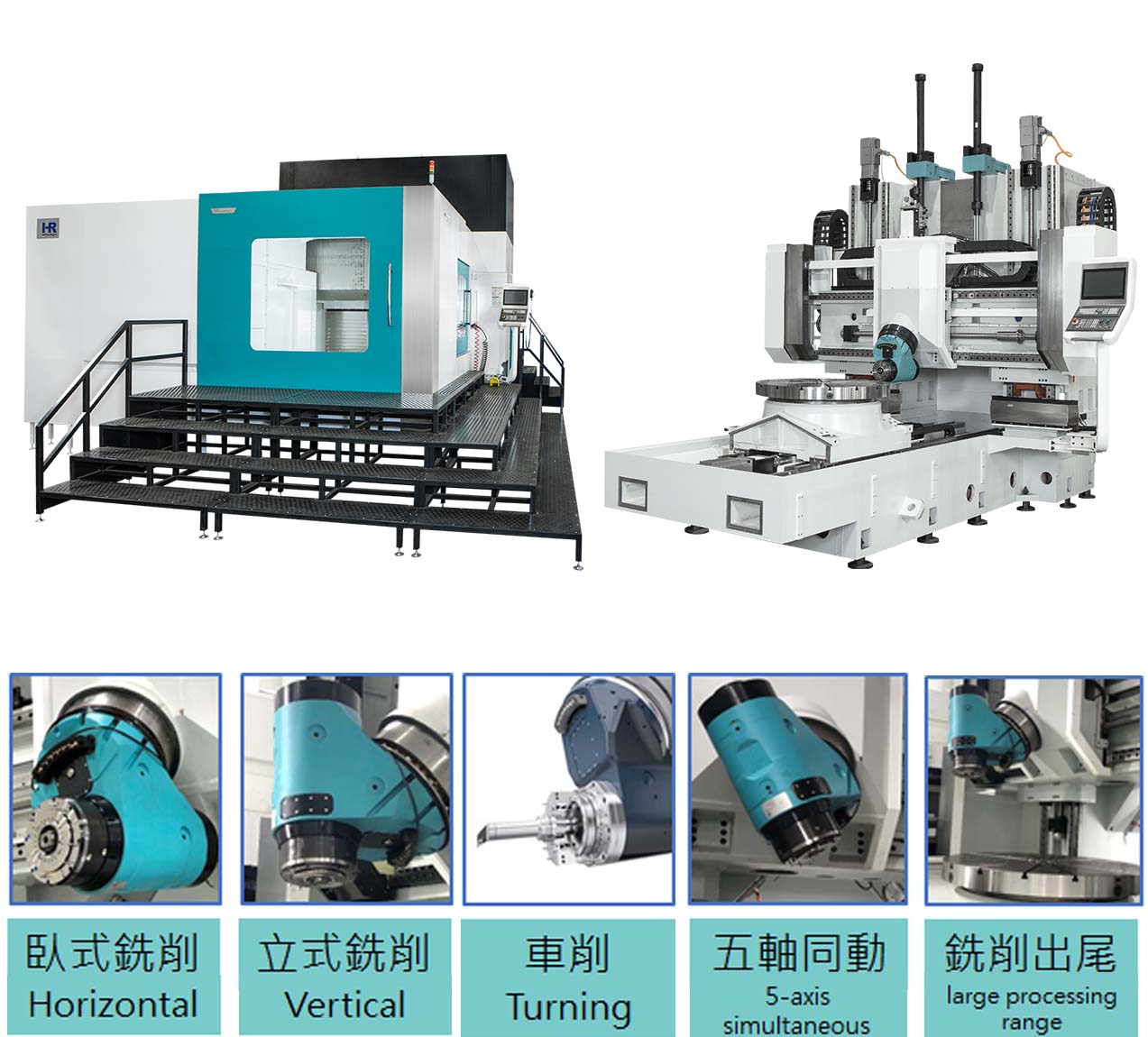

Multi-Task Machining Center

Multi-Task Machining Center Series

The range of Energy series machining centers, a portal style machine with a moving crossrail, is design to perform continuous 5-axis machining.

Main Features

Symmetrical portal for maximum guarantee of geometric precisions retention with time.

Hydraulically balanced crossrail for maximum axes dynamics and reduced energy consumption.

Milling and turning compound.

Hydrostatic guide rail rotary table

Built-in motor drive for B/C axis

Double servo Z axis moving crossrail structure enhance the machine cutting efficiency.

X/Y/Z axes rapid feed rate Max. 30/30/24 m/min , the excellent dynamic characteristics could

SINUMERIK 840D SL CNC controller with excellent five axes simultaneous machining function.

Feature

5-sided and/or 5-axis simultaneous machining, including turning, in one set-up.

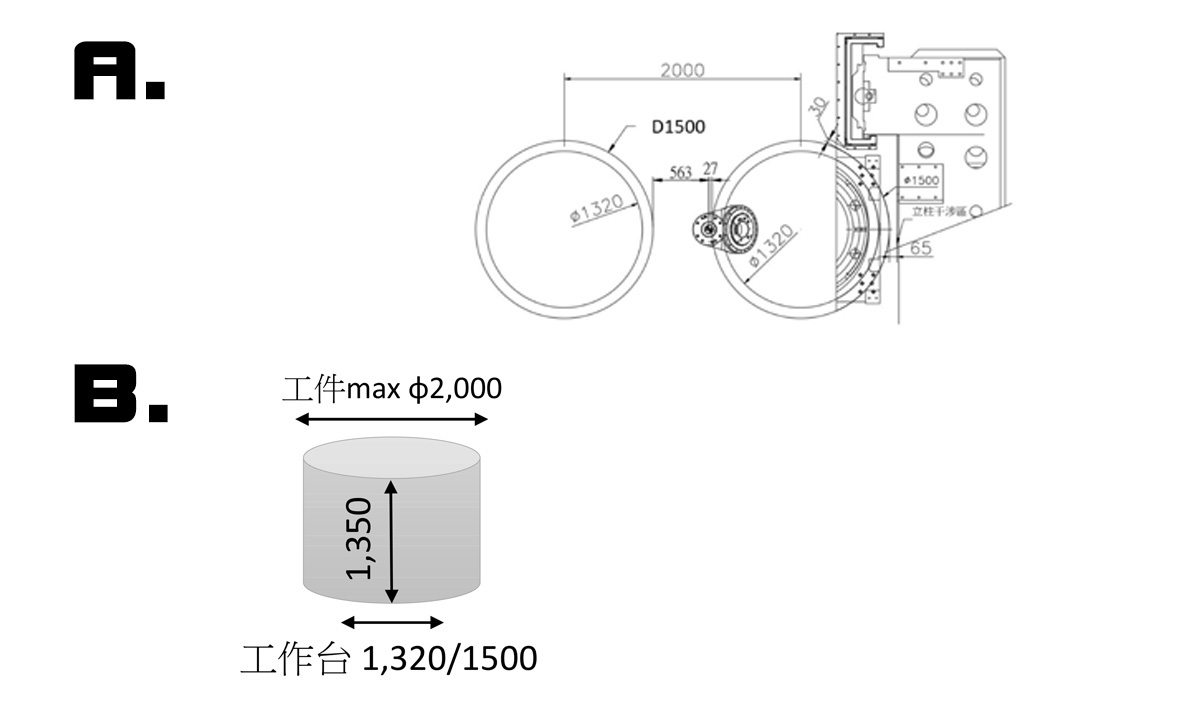

1.The vertical milling can span the φ1320 machining area.

2.It has the Z-axis measuring tool stroke under the exclusive worktable, which does not affect the processing area.

3.The moving beam Z-axis structure has the smallest overhang and the highest rigidity.。

HR Powerful Workpiece Shower System

1.Bowl-shaped workpiece chip buildup problem.

2.M Code can be used for chip removal during machining.

3.High-pressure nozzle can achieve strong chip flushing effect.

4.The spray angle can be pre-adjusted

Peripheral Equipment

Dual Side Belt Chip Conveyor

Installed within the bed, on both sides of the workstation, the dual side belt chip conveyor transports chips to the third chip conveyor located at the rear of the machine tool, before unloading them into the collection bin.

Oil Mist Recovery System

The machine includes an absorption and filtration system to capture all oil mist and coolant generated during processing.

Nut Cooling System + Heidenhain Optical Encoder

To ensure transmission accuracy, all three axes (comprising 4 sets of transmissions) are equipped with nut cooling and optical encoders for achieving the highest positioning precision.

A. Maximum Worktable Diameter:

The maximum workpiece with no interference issues regarding the X-axis travel and column, as well as the Z-axis shield, under the condition of a Φ1500 worktable diameter with the spindle center extending beyond.

B.

Specifications: D1320, 40.6KW, 4540N-m

Speed: 300 RPM

Load Capacity: 3,000 KG

HR_0-001

Non-contact tool setter + contact tool setter (for milling and turning applications)

-Laser BLUM NTH-3D

-Includes automatic lid opening

HR_0-002

Wireless transmission for part probe

-BLUM TC60

HR_0-003

Dual internal CCD cameras

-Includes industrial computer IPC 427E Win10-IPC-Standard Performance

Specifications

| Spec. | ENERGY-13 SINUMERIK 840D sl | |

|---|---|---|

| Spindle spc. | CYTEC M21-45°x10,000 rpm HSK-T100 ,53 KW | |

| Working area | X | 2000 |

| Y | 2000 | |

| Z | 1300 | |

| Workpiece maximum rotation diameter | mm | 2000 |

| Table size | mm | D1320 |

| C axis speed | rpm | 300 |

| Maximum table load | kg | 3000 |

| Chip disposal | Drag link/slat band conveyor | |

| CTS | Bar | 20/40(op.) |

| Tool magazine | PCS | 60/120T(op.) |

| Tool size (diameter x length) | mm | 250*500 |

| Tool weight max. | kg | 25 |

| Rapid traverse X / Y / Z | m/min | 30/30/24、40/40/30(OP.) |